Impeller power to viscosity calculation

How to estimate the viscosity of a fluid from the power on the agitator : case of an helix

Question or remark ? Please contact us at contact@myengineeringtools.com

Introduction

1. STEP 1 : Estimate the viscous power number of the agitator

2. STEP 2 : Calculate the viscosity

3. STEP 3 : Calculate the viscosity at other stages

4. STEP by STEP example : viscosity calculation from impeller power

5. Free Excel calculation tool for estimating the material viscosity from the power on the agitator

This page is explaining step by step how to estimate the apparent viscosity of a fluid from the power that is applied to a double helix agitator.

Introduction

In some industries such as polymer production, it is common to follow the advancement of the chemical reaction thanks to the power required to agitate the material.

Very often, the factory has references and knows that, for a given product, a given power will correspond to the right viscosity for the polymer.

It is actually possible to go further than that and, provided the characteristics of the agitator are well known, to estimate the apparent viscosity of the fluid at different stages of the process.

The method presented below is valid for helix impellers used frequently to mix polymers with high viscosity.

Figure 1 : Example of helix impeller

for viscous products (double flight)

1. STEP 1 : Estimate the viscous power number of the agitator

The power number is used to characterize the conditions of the agitation. It is possible to estimate the power number for a double helical ribbon agitator thanks to the following correlation :

With :

~Np = viscous power number (-)

D = impeller diameter (in)

T = tank diameter (in)

PH = helix pitch (in)

H = impeller height (in)

W = helix width (in)

Np = power number (-)

NRe = Reynolds number (-)

2. STEP 2 : Calculate the viscosity

Step 2.1 : Estimate the viscosity

In order to calculate the apparent viscosity of the fluid, the rotation speed of the agitator as well as the torque applied must be measured.

The power can then be calculated thanks to :

P =τ.N / 63025

With :P = power required to agitate the material (hp)

τ = torque on agitator (in.lb)

N = agitator speed (r/min)

63025 = conversion factor

The viscosity can be estimated using the viscous power number defined above :

Np_visc = P / μ.N2.D3

μ = P / Np_visc.N2.D3

Step 2.2 : correct the viscosity

From the calculated viscosity, the Reynolds number must be calculated in order to verify if the flow if laminar. if not laminar (NRe > 60), a correction factor must be applied.

NRe = D2.N.ρ / μ

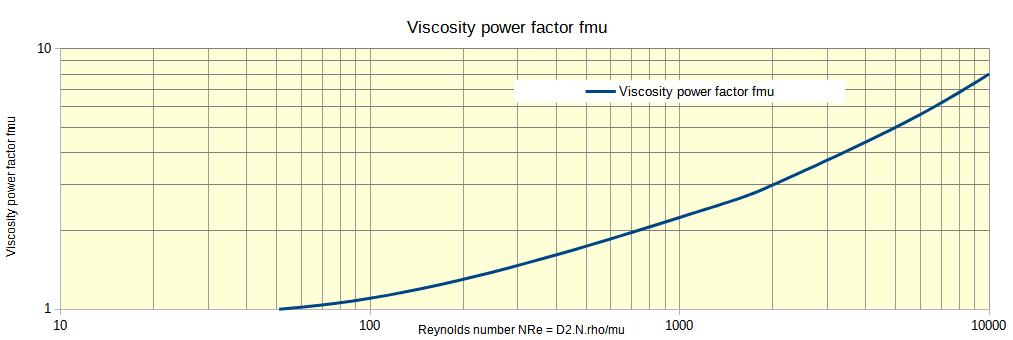

The Reynolds number allows to calculate a viscosity power factor by using the graph below :

Graph 1 : fμ as a function of NRe = D2.N.ρ/μ

Step 2.3 : re-calculate the viscosity

The actual apparent viscosity can then be calculated with :

Npactual = fμ * Np

μactual = μ / fμ

With :

Npactual = actual turbulent power number (-)

fμ = viscosity power factor (-) - see graph above

Np = power number in the geometry considered (-) - see step 1

Step 2.4 : iterate until convergence

With the new actual viscosity calculated, it is possible to calculate again the Reynold number thanks to the formula given above at step 2.2 : NRe = D2.N.ρ / μ

A new viscosity can be calculated as at step 2.3 thanks to the viscosity power factor.

Iteration stops when the viscosity recalculated is almost constant

from one iteration to another.

3. STEP 3 : Calculate the viscosity at other stages

One of the most interesting viscosity to calculate is the viscosity at the end of the polymerization process.

The same procedure can be run with the conditions of the agitation at the end of the reaction, using step 1 and 2 for those new conditions.

It is more probable that the viscosity is high enough to create a

laminar flow, thus leading to a viscosity power factor ~1 and

avoiding the iteration process.

4. STEP by STEP example : viscosity calculation from impeller power

A polymer producer is using batch reactors for the polymerization. The characteristics of the reactor are the following :

- Agitator : helical ribbon

- Diameter of the agitator D : 1.5 m

- Height of the agitator H : 1.5 m

- Blade width W : 0.15 m

- Pitch P : 1

- Diameter of the tank : T 1.6 m

- Agitator speed N : 20 rpm

- Torque measured tau : 60 N.m

- Polymer density : 850 kg/m3

STEP 1 : Estimate the viscous power number of the agitator

The power number can be estimated thanks to the geometric characteristics of the tank and agitator, D, H, W, T, P, and the following formula :

Converting D, H, W, T, P, in imperial units, Np = 259.64

Step 2.1 : Estimate the viscosity

The power of the agitator can be estimated thanks to the following formula, converting the torque in in.lb :

P =τ.N / 63025 = 531*20/63025 = 0.169 hp

Which allows to estimate the viscosity thanks to :

μ = P / Np_visc.N2.D3 = 0.169 / 259.64*202*593 = 1289.35 cP

Step 2.2 : correct the viscosity

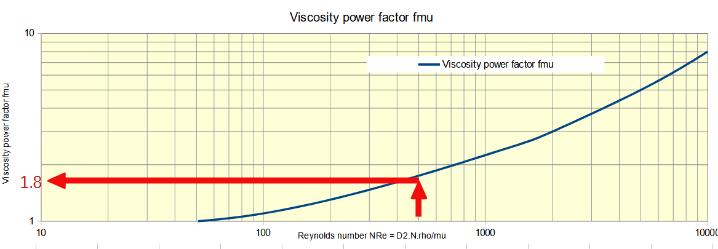

The Reynolds number can be calculated thanks to NRe = D2.N.ρ / μ

Which taking into account the units gives NRe = 10.7*592*N*0.85/644.68 = 492

The viscosity correction factor can then be calculated form the graph above :

The correction factor is thus 1.8.

Step 2.3 : re-calculate the viscosity

The apparent viscosity can be calculated thanks by dividing the previously calculated viscosity by the viscosity correction factor : mu / fmu = 716 cp

Step 2.4 : iterate until convergence

The same procedure is repeated until the viscosity calculated converges. In this particular example :

716 -> 614 -> 586 -> 573 cP

The apparent viscosity estimated is thus 573 cp.

5. Free Excel calculation tool for

estimating the material viscosity from the power on the agitator

The power required to agitate a tank can be calculated thanks to

this free Excel calculator : Calculation Tool - viscosity estimation

from agitator power

Warning : this calculator is provided to illustrate the concepts mentioned in this webpage, it is not intended for detail design. It is not a commercial product, no guarantee is given on the results. Please consult a reputable designer for all detail design you may need.

Sources

[Chopey] Handbook of Chemical Engineering calculations, Chopey et al, McGraw Hill, 2004