Comprehensive Guide to Twin Screw Pumps: Design, Applications,

and Maintenance

Follow us on Twitter Question, remark ? Contact us at contact@myengineeringtools.com

1. Mechanical Design of Twin Screw Pumps

2. Typical Applications and Limitations

4. Maximum Pressure Handling and Overpressure Protection

1. Mechanical Design of Twin Screw Pumps

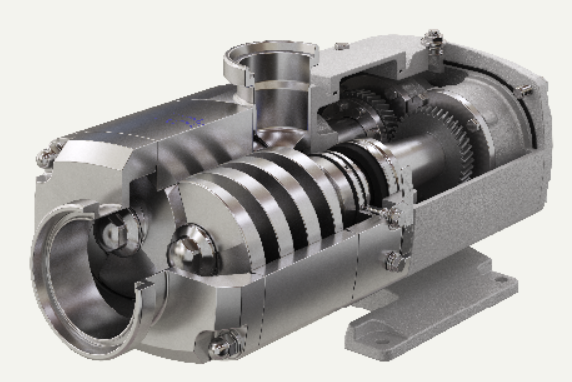

Twin screw pumps are a type of positive displacement pump appreciated for their efficiency, versatility, and ability to handle a wide range of fluids.

Key Components and Design Features

-

Screws:

- Twin intermeshing screws rotate within a tight tolerance.

- One screw is motor-driven, while the other is synchronized via a timing gear.

- The screws create sealed cavities that transport fluid from the suction side to the discharge side with minimal pulsation.

-

Casing:

- The casing is engineered to maintain close tolerances with the screws, minimizing wear and leakage.

- Materials such as stainless steel or advanced alloys are used to ensure durability and resistance to corrosion, particularly in demanding or hygienic applications.

-

Sealing Systems:

- Seals prevent fluid leakage and protect internal components from external contaminants.

- Options include mechanical seals and lip seals, selected based on fluid properties and operating conditions.

-

Materials of Construction:

- Materials are chosen to suit application needs, ranging from stainless steel for hygienic processes to specialized alloys for handling abrasive or corrosive fluids

Operational Advantages

- Pulsation-Free Flow: Ensures smooth operation, reducing mechanical stress and turbulence.

- Wide Viscosity Range: Capable of handling fluids from water-like consistency to highly viscous materials (up to 1,000,000 cP).

- Compact and Robust: Designed for space-efficient installation and longevity under challenging conditions.

- Self-Priming Capability:

- Twin screw pumps can self-prime up to 8 meters, making them suitable for applications where suction lift is required.

- Limited dry-running capability enhances operational reliability during start-up or fluid depletion scenarios.

2. Typical Applications and Limitations

Typical Applications

-

Oil and Gas Industry:

- Transporting crude oil, refined products, and lubricating oils.

- Handling multiphase fluids containing gas, liquid, and solids without separation.

-

Food and Beverage Industry:

- Pumping viscous and shear-sensitive products such as syrups, sauces, and yogurt.

- Ensuring hygiene through Clean-In-Place (CIP) operations.

-

Chemical and Pharmaceutical Industry:

- Transferring chemicals, polymers, and other reactive materials requiring precise flow control.

- Managing fluids with varying viscosities and temperatures in batch and continuous processes.

-

Water and Wastewater Treatment:

- Transporting sludge and other semi-solid materials.

- Handling abrasive particles with minimal wear in low-solids applications.

-

Marine Applications:

- Fuel oil transfer in ships and cargo unloading systems.

- Bilge and ballast water handling with high reliability under demanding conditions.

Advantages Over Other Pump Types

-

Self-Priming Capability:

- Can handle fluids containing air or gas, reducing the need for priming equipment.

- Effective in applications with intermittent flow or varying fluid levels.

-

Smooth, Pulsation-Free Flow:

- Reduces mechanical stress on piping and sensitive fluids.

- Ideal for precision processes and shear-sensitive materials.

-

Versatility:

- Efficiently handles low to extremely high viscosities, up to 1,000,000 cP.

- Suitable for abrasive and non-abrasive fluids.

-

Dual-Functionality:

- Operates as both a process pump and a CIP pump, reducing equipment needs (no need of a CIP pump).

Limitations

-

High Initial Cost:

- Twin screw pumps are more expensive compared to alternatives like diaphragm or lobe pumps.

-

Sensitivity to Abrasive Solids:

- Handling fluids with high solid content can increase wear on screws and casings, necessitating frequent maintenance.

-

Efficiency at Low Speeds:

- Performance can drop when pumping high-viscosity fluids at low operational speeds.

-

Complex Maintenance:

- While durable, maintaining close tolerances and internal

clearances requires skilled personnel and precise tools.

- While durable, maintaining close tolerances and internal

clearances requires skilled personnel and precise tools.

3. Sizing a Twin Screw Pump

Proper sizing of a twin screw pump is critical to ensure optimal performance, reliability, and efficiency. The process involves evaluating the application’s specific requirements and selecting a pump configuration that meets those needs without overloading the system or compromising longevity.

Key Factors for Sizing a Twin Screw Pump

-

Flow Rate Requirements:

- Determine the desired flow rate in cubic meters per hour (m³/h).

- Ensure the pump can meet both peak and average flow demands.

-

Viscosity of Fluid:

- Consider the viscosity of the fluid at operating temperature.

- Twin screw pumps can handle viscosities ranging from water-like fluids to extremely viscous materials up to 1,000,000 cP.

-

Discharge Pressure:

- Identify the required discharge pressure, typically measured in bar or psi.

- Twin screw pumps can handle pressures up to 40 bar (580 psi).

-

Temperature Range:

- Assess the fluid’s temperature to select materials and clearances suitable for thermal expansion.

-

Solids Content:

- Evaluate the presence and nature of solids in the fluid. While twin screw pumps can handle soft or small solids, abrasive or large particles may require special considerations.

-

Pump Speed:

- Match the pump’s speed to the fluid’s properties and the application’s requirements to optimize efficiency and reduce wear.

Motor Sizing for Twin Screw Pumps

-

Calculate Hydraulic Power (Pₕ): Use the formula:

Where:

- = Hydraulic power (kW)

- = Flow rate (m³/s)

- = Pressure difference (Pa)

- = Pump efficiency (typically 0.7–0.9)

-

Convert to Motor Power (Pₘ): Account for motor efficiency () using:

-

Apply a Safety Factor: Multiply by a safety factor (e.g., 1.25) to account for operational variations and ensure reliability.

-

Select Motor Size: Choose a motor with a standard power rating that meets or exceeds the calculated power.

Example Calculation

Given:

- Flow rate (): 10 m³/h

- Discharge pressure (): 8 bar (800,000 Pa)

- Pump efficiency (): 0.85

- Motor efficiency (): 0.9

Step 1: Convert flow rate:

Step 2: Calculate hydraulic power:

Step 3: Calculate motor power:

Step 4: Apply a safety factor:

Step 5: Select a motor size: Choose a 4 kW motor to meet the requirements.

Typical Motor Sizes for Twin Screw Pump Applications

- Low

Flow Applications (Up to 50 m³/h)

- Motor Size: Typically ranges from 2.2 kW to 7.5 kW (approximately 3 HP to 10 HP).

- Applications: Suitable for pumping low-viscosity fluids such as light oils or water in smaller systems.

- Medium

Flow Applications (50 m³/h to 200 m³/h)

- Motor Size: Generally between 7.5 kW and 15 kW (approximately 10 HP to 20 HP).

- Applications: Commonly used for hydraulic oils, lubricants, and other medium-viscosity fluids.

- High

Flow Applications (200 m³/h to 600 m³/h)

- Motor Size: Motor sizes can range from 15 kW to 37 kW (approximately 20 HP to 50 HP).

- Applications: Often found in fuel oil transfer, heavy lubricating oils, and industrial processes requiring high flow rates.

- Very

High Flow Applications (600 m³/h and above)

- Motor Size: Motors typically range from 37 kW to over 100 kW (approximately 50 HP to 150 HP).

- Applications: Used in large-scale applications such as fuel cargo handling, bitumen pumping, and other high-capacity industrial processes.

Example Applications and Corresponding Motor Sizes

- Fuel Oil Transfer: For transferring heavy fuel oils at flow rates up to 1200 m³/h, motor sizes can be around 75 kW to 100 kW.

- Hydraulic Oil Circulation: In hydraulic systems requiring medium viscosity fluids, motors of about 15 kW to 30 kW are common.

- Food Processing: For hygienic applications with varying viscosities, motor sizes may range from 5 kW to 15 kW, depending on the specific requirements.

4. Maximum Pressure Handling and Overpressure Protection

Twin screw pumps are designed to handle high pressures, making them suitable for demanding applications. Proper management of pressure and protection against overpressure conditions is crucial to ensure safe and efficient operation.Maximum Pressure Handling

-

Typical Pressure Range:

- Twin screw pumps can typically handle discharge pressures up to 40 bar (approximately 580 psi), depending on the design and materials of construction.

-

Factors Influencing Pressure Capability:

- Material Strength: Pumps made of advanced alloys or stainless steel can withstand higher pressures.

- Clearance Design: Close tolerances minimize leakage and ensure pressure stability.

- Operational Speed: Proper speed adjustment is essential to maintain pressure without exceeding design limits.

-

Applications Requiring High Pressure:

- Oil transfer in pipelines.

- Chemical processing where precise flow control under high pressure is needed.

- Marine applications, such as fuel injection systems.

Overpressure Protection

Overpressure conditions can occur due to system blockages, sudden demand changes, or equipment failure. Implementing protection measures is essential to prevent damage to the pump and associated systems.

-

Pressure Relief Valves (PRVs):

- Install PRVs on the discharge side to release excess pressure safely.

- Set the valve to activate slightly above the pump's maximum operating pressure.

-

Burst Discs:

- Employ burst discs as a secondary safety measure to rupture and relieve pressure if PRVs fail.

-

Pressure Monitoring Systems:

- Use electronic pressure sensors and alarms to provide real-time feedback on system pressure.

- Automate shutdown protocols to protect the pump during abnormal conditions.

-

Variable Speed Drives (VSDs):

- Dynamically adjust pump speed based on pressure feedback to reduce the risk of overpressure.

- Enhance energy efficiency by matching pump performance to system demand.

Maintenance Considerations

- Regularly inspect and test pressure relief devices to ensure proper function.

- Monitor system performance for signs of pressure instability, such as excessive vibration or noise.

- Conduct preventive maintenance on seals and bearings to minimize

risks associated with high-pressure operation.

5. Specific operations of twin screw pumps

Twin screw pumps are versatile devices capable of performing specialized operations that enhance their applicability across a wide range of industrial processes. Their unique capabilities include self-priming, reverse operation, and dry running.5.1 Self-Priming

Overview: Twin screw pumps are inherently self-priming, capable of creating sufficient suction lift to start operations without additional priming devices.

-

Ease of Startup:

- Can lift fluids from up to 8 meters below the pump inlet.

- Ideal for applications where the pump needs to operate in conditions with varying fluid levels or intermittent flow.

-

Handling Varying Fluid Conditions:

- Effectively manages fluids with entrained air, gases, or light foaming.

- Suitable for chemical processing, food production, and marine applications.

-

High Suction Lift Capability:

- Enables fluid transfer over significant vertical distances, such as drawing liquids from underground tanks.

-

Operational Efficiency:

- Reduces downtime and simplifies system design by eliminating the need for separate priming systems.

5.2 Reverse Operation

Twin screw pumps can run in reverse without structural or operational modifications.

-

Bidirectional Flow:

- By reversing the rotation of the screws, the pump can transfer fluid in the opposite direction.

- Enhances operational flexibility and reduces the need for additional equipment.

-

Applications:

- Product Recovery: Minimize waste by retrieving residual fluids from the system before cleaning or shutdown.

- Cleaning Cycles: Assist in flushing pipelines by reversing the flow.

- System Flexibility: Clear blockages or redirect fluid paths during maintenance or emergencies.

-

Considerations:

- Verify the functionality of pressure relief valves and other components, as they may be unidirectional.

5.3 Dry Running Capability

Twin screw pumps can tolerate limited periods of dry running without significant damage, a feature that sets them apart from many other pump types.

-

Key Advantages:

- Operate without fluid for short durations during startup or interruptions in supply.

- Reduce risks of damage due to unintentional dry running.

-

Operational Benefits:

- Simplifies maintenance and cleaning processes, as the pump can be operated briefly to clear fluids.

- Enhances reliability in applications involving low fluid levels or entrained air.

-

Limitations:

- Prolonged dry running can cause wear on internal components. Monitoring systems are recommended to minimize risks.

Twin screw pumps can run dry for limited periods without sustaining damage, but the exact duration can vary based on several factors, including the pump's design and the specific operating conditions. Here are the key points regarding how long a twin screw pump can run dry before it risks damage:

1. Short Duration Tolerance

- Twin screw pumps are designed to tolerate dry running for short intervals, typically ranging from a few minutes to about 15-30 minutes. However, this is highly dependent on the specific pump model and its construction materials.

2. Potential Damage Risks

- Running dry generates frictional heat in the seals and other internal components, which can lead to wear and eventual failure. Mechanical seals may wear quickly due to lack of lubrication, potentially causing leaks and further damage to the pump

- Damage can manifest as scoring or abrasion on the screws and housing, leading to reduced efficiency and increased maintenance costs

3. Manufacturer Guidelines

- It

is crucial to consult the manufacturer's specifications for each

specific twin screw pump model. Some pumps may have enhanced

designs that allow for slightly longer dry running times without

significant risk of damage, while others may be more sensitive

to prolonged dry operation

4. Best Practices

- To minimize risks associated with dry running, it is advisable to implement monitoring systems that can alert operators if the pump is running without fluid.

- Regular maintenance and inspections can help identify potential issues before they lead to significant damage.

5.4 Pumping Abrasive Materials

Overview: Twin screw pumps can handle abrasive fluids, but precautions are necessary to ensure durability and performance.

-

Design Considerations:

- Use wear-resistant materials for screws and casings.

- Minimize clearances to reduce internal fluid slip and maintain efficiency.

-

Limitations:

- Handling highly abrasive or large solid particulates can accelerate wear and require frequent maintenance.

- Pump efficiency may be reduced when operating with abrasive fluids.

6. Common Issues and Troubleshooting for Twin Screw Pumps

Twin screw pumps are reliable but can encounter operational issues. A structured troubleshooting approach simplifies diagnosis and resolution, ensuring minimal downtime.

Common Issues and Solutions

| Issue | Possible Causes | Solutions |

|---|---|---|

| No Flow or Irregular Flow | - Incorrect rotation direction. - Insufficient suction pressure or air in suction line. - Blocked piping. | - Verify motor rotation direction. - Check suction pressure and vent air from the system. - Inspect and clear blockages. |

| Overheating | - Pumping high-viscosity fluids. - Inadequate cooling or lubrication. | - Adjust speed or preheat fluids to lower viscosity. - Ensure cooling systems are operational. |

| Excessive Noise or Vibration | - Misalignment of pump and motor. - Cavitation due to low suction head. - Worn screws or bearings. | - Align pump and motor shafts. - Increase suction head or reduce pump speed. - Replace worn components. |

| Pressure Fluctuations | - Blocked or partially closed valves. - Inconsistent fluid supply. | - Inspect and fully open valves. - Stabilize fluid supply upstream. |

| Seal Leakage | - Worn or damaged seals. - Pressure/temperature beyond seal limits. | - Replace seals with new ones. - Verify system pressure and temperature within seal specifications. |

| Reduced Efficiency | - Increased internal clearance due to wear. - Operating outside optimal range. | - Rebuild or replace worn screws and casing. - Adjust parameters to align with specifications. |

Preventive Maintenance

| Measure | Description |

|---|---|

| Regular Inspections | Schedule checks for wear on screws, seals, bearings, and casings. |

| Component Cleaning | Remove debris and lubricate regularly to reduce wear and friction. |

| Monitoring Systems | Install sensors for temperature, pressure, and flow for early anomaly detection. |

| Avoid Dry Running | Minimize or eliminate dry running to prevent internal component damage. |

| Cavitation Prevention | Maintain appropriate suction conditions to prevent fluid vaporization and cavitation. |

Troubleshooting Checklist

| Step | Action |

|---|---|

| Visual Inspection | Look for visible leaks, misalignments, or physical wear on components. |

| Performance Testing | Compare flow rate, pressure, and efficiency against design parameters. |

| Component Assessment | Inspect screws, seals, and bearings for signs of damage, wear, or misalignment. |

| Monitor System Readings | Evaluate pressure, temperature, and vibration trends for deviations from normal operating conditions. |

Twin screw pumps FAQ

| Question | Answer |

|---|---|

| What is a twin screw pump? | A twin screw pump is a type of positive displacement pump that uses two intermeshing screws to transport fluids. The synchronized rotation of the screws creates cavities that draw in and push out fluid, providing a steady, non-pulsating flow. This design makes them suitable for handling various fluids, including those with high viscosities or containing solids. |

| What are the typical applications of twin screw pumps? | Twin screw pumps are widely used in industries such as oil and gas, food processing, chemical manufacturing, and marine applications. They are ideal for transferring viscous fluids, slurries, and products requiring hygienic handling. |

| How do I determine the right size for a twin screw pump? | Sizing involves calculating the required flow rate, discharge pressure, fluid viscosity, and considering factors such as NPSH (Net Positive Suction Head). Consult manufacturer guidelines and consider the specific application requirements to ensure optimal performance. |

| What is the maximum viscosity a twin screw pump can handle? | Twin screw pumps can handle viscosities up to 1,000,000 cP, depending on the specific design and configuration of the pump. High-viscosity fluids may require adjustments in motor size or pump speed to maintain efficiency. |

| Can twin screw pumps run dry? | Yes, twin screw pumps can run dry for limited periods without damage. However, prolonged dry running should be avoided as it can lead to wear on seals and other components. Typically, they can operate dry for about 15-30 minutes, depending on the model and operating conditions. |

| What maintenance is required for twin screw pumps? | Regular maintenance includes routine inspections for leaks or wear, cleaning suction strainers, checking lubrication levels, inspecting seals and gaskets, and conducting performance tests. Establishing a maintenance schedule based on operational hours will help ensure longevity and reliability. |

| What are common issues faced with twin screw pumps? | Common issues include no flow or irregular flow due to insufficient suction pressure, air ingress in the suction line, high viscosity fluids exceeding design limits, and mechanical wear on screws or seals. Regular troubleshooting checks can help identify these problems early. |

| How efficient are twin screw pumps? | Twin screw pumps typically operate at efficiencies between 80% and 90%, while associated electrical drives generally have efficiencies ranging from 85% to 95%. Overall system efficiency can vary but is generally between 70% and 85% when accounting for both pump and motor efficiencies. |

| What factors affect the performance of a twin screw pump? | Performance can be influenced by fluid viscosity, temperature, pressure conditions, NPSH available, pump speed, and the presence of solids or gas in the fluid. Properly sizing the pump and motor while considering these factors is crucial for optimal operation. |

| Can I customize a twin screw pump for specific applications? | Yes, twin screw pumps can be highly customized to meet specific operational requirements. Customizations may include special coatings for corrosion resistance, specific seal arrangements, varied screw profiles or pitches for efficiency adjustments, and modifications to accommodate unique process conditions. |

Source

[1] https://jieyatwinscrew.com/blog/twin-screw/

[2] https://www.spxflow.com/blog/is-twin-screw-pump-right-for-you/

[3] https://baosteelpump.com/screw-pump-selection-guide/

[4]

https://www.tapflopumps.co.uk/knowledge-article/twin-screw-pump-troubleshooting/

[5]

https://www.northridgepumps.com/article-203_screw-pump-troubleshooting-guide

[6]https://onepetro.org/PO/article/3/04/629/75596/Development-of-a-Twin-Screw-Pump-for-Multiphase

[7]

https://www.michael-smith-engineers.co.uk/resources/useful-info/twin-screw-pumps

[8]https://www.csidesigns.com/blog/articles/how-do-you-know-when-your-application-requires-a-twin-screw-pump

[9]

https://www.northridgepumps.com/p_1303_north-ridge-2sp-series-twin-screw-pump

[10]https://www.lakeside-equipment.com/screw-pump-troubleshooting-common-problems-and-solutions/

[11] https://www.northridgepumps.com/article-233_screw-pump-guide

[12]https://baosteelpump.com/the-advantages-and-disadvantages-of-different-types-of-screw-pumps/

[13] https://pumps.circor.com/products/twin-screw-pump

[14]https://assets.alfalaval.com/documents/pca641d5c/alfa-laval-manual-guidelines-twin-screw-pumps-en.pdf

[15]https://www.alfalaval.sg/products/fluid-handling/pumps/twin-screw-pump/twin-screw/