Check valves : calculate the minimum velocity for full opening,

step by step calculation guide

Follow us on Twitter ![]()

Question, remark ? Contact us at contact@myengineeringtools.com

1. Check valves

2. Check valves noise and vibration

1. Check valves

Check valves are ubiquitous in piping Engineering, they are used to ensure that the flow of fluid can happen in a single direction. There are different design that can be chosen depending on the application.

At its core, a check valve acts as a one-way gate for fluid flow. It allows unrestricted flow in the desired direction while automatically closing to prevent any backflow. This is achieved through a closing element, typically a disc, ball, or flap, that opens and closes in response to the pressure differential across the valve. This simple yet effective mechanism ensures that the fluid travels in the intended direction, preventing potentially detrimental consequences.

2. Check valves noise and vibration

Top

5 Most Popular

1. Pressure drop

2. Reynolds Number

3.

Pressure drop K coefficients

4. Churchill equation

5. Moody diagram

Check valves can present several issues for factories, one of the most common issues is to have a noisy check valve which is quickly getting worn out. One of the reason of having a noisy check valve is that it opens and close very quickly, this can happen if the fluid velocity is not enough to keep fully opened the plug or disc of the check valve.

It is thus key to design the check valve so that the flow through the valve is above the minimum pipe velocity for full disc lift.

3. Step by Step calculation of minimum pipe velocity for full disc lift of check valves

3.1 Step 1 : select a check valve

There are different kinds of common check valves :

- Swing check valves

- Lift check valves

- Tilting disc check valves

- Stop check valves

- Foot valves (special types)

3.2 Step 2 : Get the coefficient of the check valve

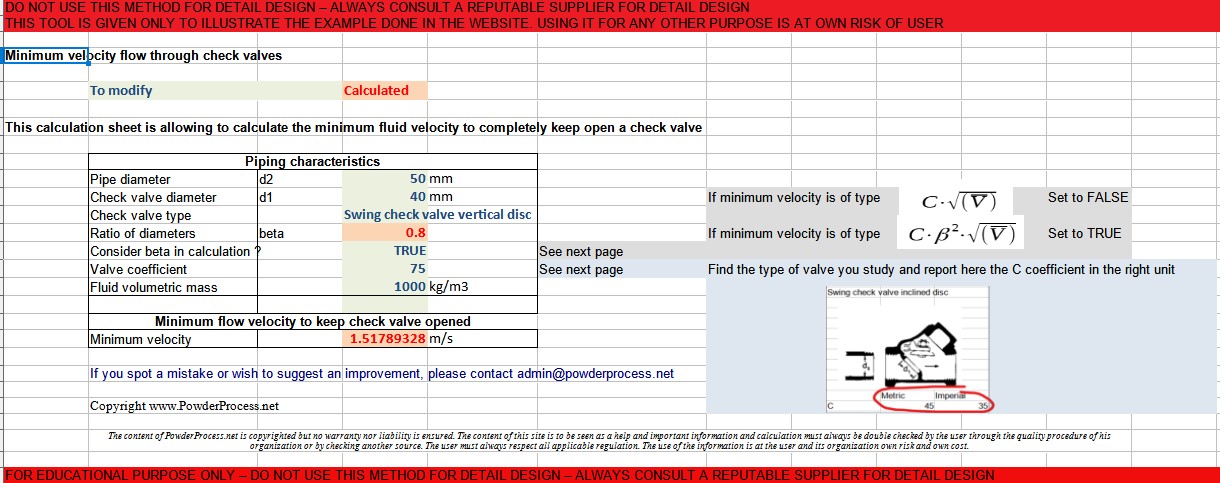

Check valves are given a coefficient C that is to be used in calculating the minimum velocity. The C coefficients for different check valve design can be found in the Excel calculator below.

3.3 Step 3 : Get the format of velocity calculation for the design studied

The minimum velocity can be calculated the following way :

vmin = C.(1/ρ)1/2

or

vmin = C.β2.(1/ρ)1/2

With :

vmin = minimum fluid velocity to keep the check valve

open (m/s)

C = valve coefficient

β = d1/d2

d1 = valve opening diameter (mm)

d2 = pipe diameter (mm)

ρ = volumetric mass of the fluid (kg/m3)

The format to be used for each of the check valve design can be found in the Excel calculator below.

3.4 Step 4 : Calculate the minimum velocity to keep the check valve fully open

Replace in the formula C, beta and rho by their value.

4. Check valve minimum velocity Excel calculator

How to calculate the minimum velocity to keep a check valve fully open ?

You can access to an Excel calculation tool in order to calculate the minimum fluid velocity in a pipe required to keep a check valve fully open : Check valve minimum fluid velocity Excel calculation tool (click here)

Warning : this calculator is provided to illustrate the concepts mentioned in this webpage, it is not intended for detail design. It is not a commercial product, no guarantee is given on the results. Please consult a reputable designer for all detail design you may need.

Source :