Control valve types

Valve types and typical flow parameters

Follow us on Twitter ![]()

Question, remark ? Contact us at contact@myengineeringtools.com

1. Globe valves

4. Gate Valves

This page is giving details about the design of the main valve types found in process industries for process control. For sizing the valves, please refer to the following pages :

- Valve Cv and capacity calculation for liquid and gas flow

- Valve Cv and capacity calculation for steam and superheated steam

- Valve Cv and capacity calculation for laminar flow

1. Globe valves

What is a globe valve ?

Globe valves are among the most popular design for control valves as they allow usually a fine regulation that cannot be reached by butterfly valves, ball valves or gate valves. The flow in between the inlet and outlet of the valve is regulated thanks to a plug that can rest on a seat to close the valve or get lifted in order to allow the flow of fluid.

They are named globe valves because of the globular shape of the cavities within the valve body.

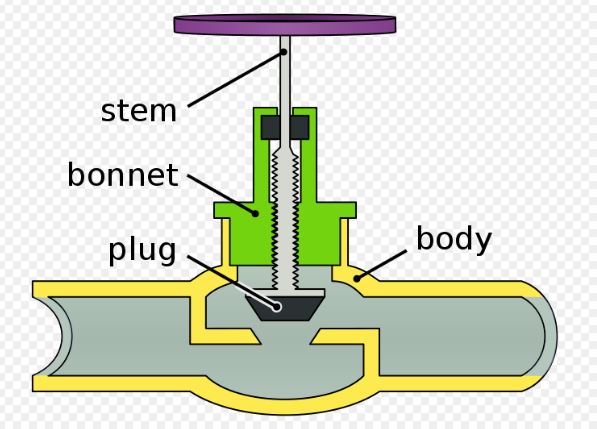

Figure 1 : globe valve [Aimonen]

Figure 2 : globe valve [Padleckas]

1. body

2. ports

3. seat

4. stem

5. disc or plug when valve is

open

6. handle or handwheel when

valve is open

7. bonnet

8. packing

9. gland nut

10. fluid flow when valve

is open

11. position of disc if valve were shut

12. position of handle or handwheel if valve were shut

The plug, cage (see below), seat rings and seals are called the trim.

The drawings above represent the most popular type of globe valve. An alternative design exists where the plug is within a cage. Lifting the plug is releasing passageway for the product to flow.

Flow parameters of globe valves

The values below are given by [Emerson] and can be used in basic design to have a rough idea of the size of the valve to select :

| Valve size (NPS) | Valve plug type | Flow characteristic | Port diameter (in) | Rated travel (in) | Cv | FL | XT | FD |

| 1/2 | Post-Guided | Equal-Percentage | 0.38 | 0.5 | 2.41 | 0.9 | 0.54 | 0.61 |

| 3/4 | Post-Guided | Equal-Percentage | 0.56 | 0.5 | 5.92 | 0.84 | 0.61 | 0.61 |

| 1 | Micro-Form | Equal-Percentage | 3/8 | 3/4 | 3.07 | 0.89 | 0.66 | 0.72 |

| 1 | Micro-Form | Equal-Percentage | 1/2 | 3/4 | 4.91 | 0.93 | 0.8 | 0.67 |

| 1 | Micro-Form | Equal-Percentage | 3/4 | 3/4 | 8.84 | 0.97 | 0.92 | 0.62 |

| 1 | Cage guided | Linear | 1-5/16 | 3/4 | 20.6 | 0.84 | 0.64 | 0.34 |

| 1 | Cage guided | Equal-Percentage | 1-5/16 | 3/4 | 17.2 | 0.88 | 0.67 | 0.38 |

| 1-1/2 | Micro-Form | Equal-Percentage | 3/8 | 3/4 | 3.2 | 0.84 | 0.65 | 0.72 |

| 1-1/2 | Micro-Form | Equal-Percentage | 1/2 | 3/4 | 5.18 | 0.91 | 0.71 | 0.67 |

| 1-1/2 | Micro-Form | Equal-Percentage | 3/4 | 3/4 | 10.2 | 0.92 | 0.8 | 0.62 |

| 1-1/2 | Cage guided | Linear | 1-7/8 | 3/4 | 39.2 | 0.82 | 0.66 | 0.34 |

| 1-1/2 | Cage guided | Equal-Percentage | 1-7/8 | 3/4 | 35.8 | 0.84 | 0.68 | 0.38 |

| 2 | Cage guided | Linear | 2-5/16 | 1-1/8 | 72.9 | 0.77 | 0.64 | 0.33 |

| 2 | Cage guided | Equal-Percentage | 2-5/16 | 1-1/8 | 59.7 | 0.85 | 0.69 | 0.31 |

| 3 | Cage guided | Linear | 3-7/16 | 1-1/2 | 148 | 0.82 | 0.62 | 0.3 |

| 3 | Cage guided | Equal-Percentage | 3-7/16 | 1-1/2 | 136 | 0.82 | 0.68 | 0.32 |

| 4 | Cage guided | Linear | 4-3/8 | 2 | 236 | 0.82 | 0.69 | 0.28 |

| 4 | Cage guided | Equal-Percentage | 4-3/8 | 2 | 224 | 0.82 | 0.72 | 0.28 |

| 6 | Cage guided | Linear | 7 | 2 | 433 | 0.84 | 0.74 | 0.28 |

| 6 | Cage guided | Equal-Percentage | 7 | 2 | 394 | 0.85 | 0.78 | 0.26 |

| 8 | Cage guided | Linear | 8 | 3 | 846 | 0.87 | 0.81 | 0.31 |

| 8 | Cage guided | Equal-Percentage | 8 | 3 | 818 | 0.86 | 0.81 | 0.26 |

Manufacturers of globe valves

In order to get quotes, prices of globe valves, the reader can refer to the following companies which are supplying globe valves :

- Guichon valves : http://guichon-vannes.com/

- Sart Von Rohr valves : www.sart-von-rohr.fr

- Gemu valves :

gemu-group.com

2. Angle valves

What is an angle valve ?

An angle valve is a special design of globe valve. The inlet and outlet are however at 90°. This can be interesting to self drain the outlet of the valve.

3. Butterfly valves

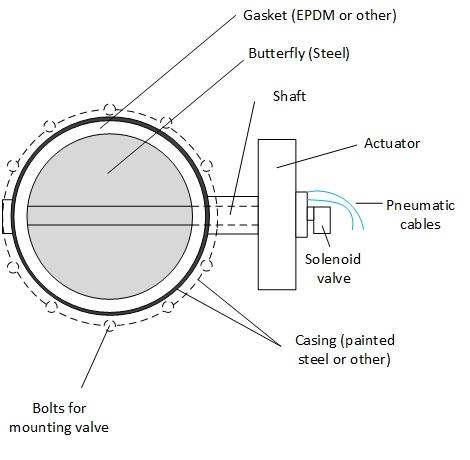

What is a butterfly valve ?

Butterfly valves, compared to globe valves present the advantage to have a very low resistance to the fluid flow when opened, which means they can reach high Cv for relatively small sizes.

They however offer a less fine control of the flow during regulation.

Butterfly valves can be available without gasket, the sealing is then done metal / metal which means there is a leakage. The leakage is reduced or avoided when using a polymer gasket. The material for the gasket must be chosen according to the service of the valve.

Note that a it is possible to have the disc that is offset from the shaft centerline which allows to reduce friction and wear when moving the valve. Such design is called an eccentric butterfly valve or a high performance butterfly valve.

Flow parameters of butterfly valves

The values below are given by [Emerson] and can be used in basic design to have a rough idea of the size of the valve to select :

| Valve size (NPS) | Degree of opening | Cv | FL | XT | FD |

| 2 | 60 | 58.9 | 0.76 | 0.5 | 0.49 |

| 2 | 90 | 80.2 | 0.71 | 0.44 | 0.7 |

| 3 | 60 | 115 | 0.81 | 0.46 | 0.49 |

| 3 | 90 | 237 | 0.64 | 0.28 | 0.7 |

| 4 | 60 | 270 | 0.69 | 0.32 | 0.49 |

| 4 | 90 | 499 | 0.53 | 0.19 | 0.7 |

| 6 | 60 | 664 | 0.66 | 0.33 | 0.49 |

| 6 | 90 | 1260 | 0.55 | 0.2 | 0.7 |

| 8 | 60 | 1160 | 0.66 | 0.31 | 0.49 |

| 8 | 90 | 2180 | 0.48 | 0.19 | 0.7 |

| 10 | 60 | 1670 | 0.66 | 0.38 | 0.49 |

| 10 | 90 | 3600 | 0.48 | 0.17 | 0.7 |

| 12 | 60 | 2500 | '- | '- | 0.49 |

| 12 | 90 | 5400 | '- | '- | 0.7 |

| 16 | 60 | 3870 | 0.69 | 0.4 | '- |

| 16 | 90 | 8600 | 0.52 | 0.23 | '- |

Alternatively, [Midoux] is giving the following general relations :

Cv/Dv2 = 5.10-2*f2

f=(90-θ)/90

and FL ~ 0.675

With

Dv = nominal diameter of the valve (m)

θ = degree of opening (degrees) - 90 degrees is closed

Cv is given in m3/s (possible to convert in gpm by multiplying this

value by 1.32*106)

Example : 4 inch valve at 90 degrees opening.

f=1

Cv=5.10-2*(0.1016)2=5.16*10-4 m3/s

Cv=681 gpm

Fl = 0.675

This is quite in accordance with the table above (Cv = 499, FL=0.53)

Manufacturers of butterfly valves

In order to get quotes, prices of butterfly valves, the reader can refer to the following companies which are supplying wafer valves :

- Buracco : www.buracco.com

- Robvalve : https://robvalve.wixsite.com/

- ABZ valves

- Keystone butterfly valves

- Nibco butterfly valves

4. Gate valves

What is a gate valve ?

Manufacturers of gate valves

In order to get quotes, prices of gate valves, the reader can refer to the following companies which are supplying gate valves :

- UCMA valves : www.ucmasn.fr

- PAM valves : https://www.pamline.fr/catalog/details/RASRV28VAG711

5. Ball valves

What is a ball valve ?

The name ball valve comes from the fact that the closing element has the shape of a ball. This ball has actually a hole that allows to let the fluid pass when open. When closed, the plain side of the ball faces the fluid and allows a rather tight seal.

Segmented ball valves or V-notch ball valves also exist.

Flow parameters of ball valves

The values below are given by [Emerson] for V-notch ball valves and can be used in basic design to have a rough idea of the size of the valve to select :

| Valve size (NPS) | Degree of opening | Cv | FL | XT | FD |

| 1 | 60 | 15.6 | 0.86 | 0.53 | '- |

| 1 | 90 | 34 | 0.86 | 0.42 | '- |

| 1-1/2 | 60 | 28.5 | 0.85 | 0.5 | '- |

| 1-1/2 | 90 | 77.3 | 0.74 | 0.27 | '- |

| 2 | 60 | 59.2 | 0.81 | 0.53 | '- |

| 2 | 90 | 132 | 0.77 | 0.41 | '- |

| 3 | 60 | 120 | 0.8 | 0.5 | 0.92 |

| 3 | 90 | 321 | 0.74 | 0.3 | 0.99 |

| 4 | 60 | 195 | 0.8 | 0.52 | 0.92 |

| 4 | 90 | 596 | 0.62 | 0.22 | 0.99 |

| 6 | 60 | 340 | 0.8 | 0.52 | 0.91 |

| 6 | 90 | 1100 | 0.58 | 0.2 | 0.99 |

| 8 | 60 | 518 | 0.82 | 0.54 | 0.91 |

| 8 | 90 | 1820 | 0.54 | 0.18 | 0.99 |

| 10 | 60 | 1000 | 0.8 | 0.47 | 0.91 |

| 10 | 90 | 3000 | 0.56 | 0.19 | 0.99 |

| 12 | 60 | 1530 | 0.78 | 0.49 | 0.92 |

| 12 | 90 | 3980 | 0.63 | 0.25 | 0.99 |

| 16 | 60 | 2380 | 0.8 | 0.45 | 0.92 |

| 16 | 90 | 8270 | 0.37 | 0.13 | 1 |

Manufacturers of ball valves

In order to get quotes, prices of ball valves, the reader can refer to the following companies which are supplying ball valves :

- Guichon valves : http://guichon-vannes.com/

- GRK valves : https://www.grk.fr/

[Padleckas] Globe valve drawing on Wikimedia Commons

[Emerson] Control Valve Handbook 5th edition, Emerson Fisher

[Midoux] Mecanique et Rheologie des Fluides, page 392, Midoux, Lavoisier