Steam cost calculation

What is the cost of steam generation in a factory ?

Follow us on Twitter ![]()

Question, remark ? Contact us at contact@myengineeringtools.com

1. Steam cost : calculation method

The cost of fuel is on the rise and will stay on long term due to the rarefaction of oil and gas as reserves worldwide are depleted. Process industries however still need such fuels and a common application is to produce steam. Steam will be used in many aspects of the process, as utility (process heating for instance) or as part of the process / formulation.

Steam generation is thus expensive as it is done in boilers running with oil or gas. Being able to track the cost of steam is necessary to make sure that the factory remains profitable. Understanding how much cost steam is also a powerful motivator to look for energy savings (look for leaky steam traps, install steam turbines to recover energy...).

The present page presents a shortcut method to estimate the cost of steam produced in a factory.

1. Steam cost : calculation method

[Hall[ is proposing a shortcut calculation to estimate the cost of steam. It is in 2 steps, 1st calculate the cost of the fuel, 2nd calculate the cost of steam by integrating other factors.

1.1 Step 1 : calculate the cost of fuel

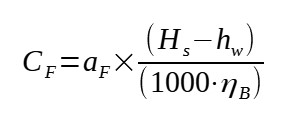

The cost of fuel used for steam generation can be calculated as :

CF = aF * (Hs-hw) / (1000*ηB)

With :

CF = cost of fuel ($/1000lb steam generated)

aF = cost of fuel for the boiler ($/MMBtu)

Hs = enthalpy of steam (Btu/lb)

hw = enthalpy of boiler feedwater (Btu/lb)

ηB = overall boiler efficiency

The typical efficiency of a boiler is around 80%.

Top 5 Most

Popular

1. Compressor

Power Calculation

2. Pump Power Calculation

3. Pipe Pressure

Drop Calculation

4. Fluid Velocity in pipes

5. Churchill Correlation

(friction factor)

1.2 Step 2 : calculate the cost of steam

The cost of steam is mainly coming from the cost of fuel, however there are many other costs to be considered (cost of raw water, treatment of feedwater, pumping/fan power, sewer charges, environmental costs, maintenance and labor...). To take this into account, a 30% markup is put on top of the fuel cost. This is of course an approximation, but is sufficient to get a sense of the overall steam cost. More detailed studies should estimate the cost of each of these other contributors to the steam cost.

CG = CF*(1+0.3)

With :

CG = cost of steam ($/1000lb steam generated)

CF = cost of fuel ($/1000lb steam generated)

2. Steam generation tips

In order to optimize further the usage of steam in the factory, please keep in mind the following :

- Steam usage in a process plant is mainly for heating purpose (60% of thermal energy use)

- When having low pressure steam available, consider using a steam turbine to recover energy, especially if the flow rate of steam is >20000 kg/h

- Low pressure steam resulting from using a pressure reducing valve on high pressure steam will result in similar cost of steam in between low pressure and high pressure steam

- 90% of heat loss from a hot uninsulated pipe can be prevented by proper insulation

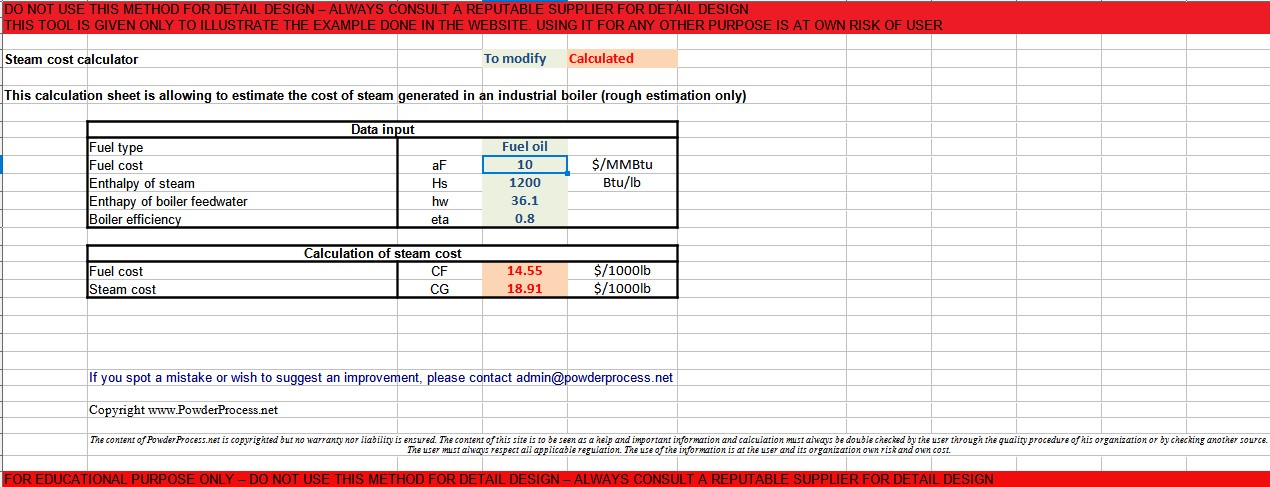

3. Steam cost Excel calculator

How to calculate the cost of steam generated in an industrial boiler ?

You can access to an Excel calculation tool in order to get a rough estimate of the steam cost from an industrial boiler : Steam Cost Excel calculation tool (click here)

Warning : this calculator is provided to illustrate the concepts mentioned in this webpage, it is not intended for detail design. It is not a commercial product, no guarantee is given on the results. Please consult a reputable designer for all detail design you may need.

Sources

[Hall] Rules of Thumb for Chemical Engineers, Hall, Elsevier, page 346