A Comprehensive Guide to Check Valves in Piping Systems

Follow us on Twitter ![]()

Question, remark ? Contact us at contact@myengineeringtools.com

1. Introduction

2. Design Considerations of Check Valves

1. Introduction

In the intricate world of piping systems, the role of check valves

is paramount. These unassuming devices serve as silent guardians,

preventing the backflow of fluids and ensuring the smooth operation

of numerous industrial processes. In this comprehensive guide, we'll

explore the different types of check valves, delve into critical

design considerations, and address common troubleshooting issues.

Let's unlock the potential of check valves in piping systems.

The different Types of Check Valves

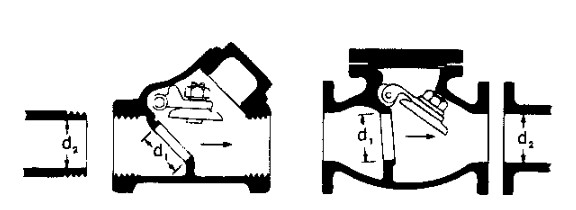

Swing Check Valves : Swing check valves are known for their simple yet effective design. The swinging disc allows fluid to flow in one direction while preventing backflow. Pros include low maintenance requirements, but they may be limited in high-flow applications and are susceptible to water hammer.

Lift Check Valves : Lift check valves, suitable for vertical pipelines, operate by lifting the disc against gravity during flow. They offer less pressure drop but can be prone to water hammer and might not be ideal for high-pressure systems.

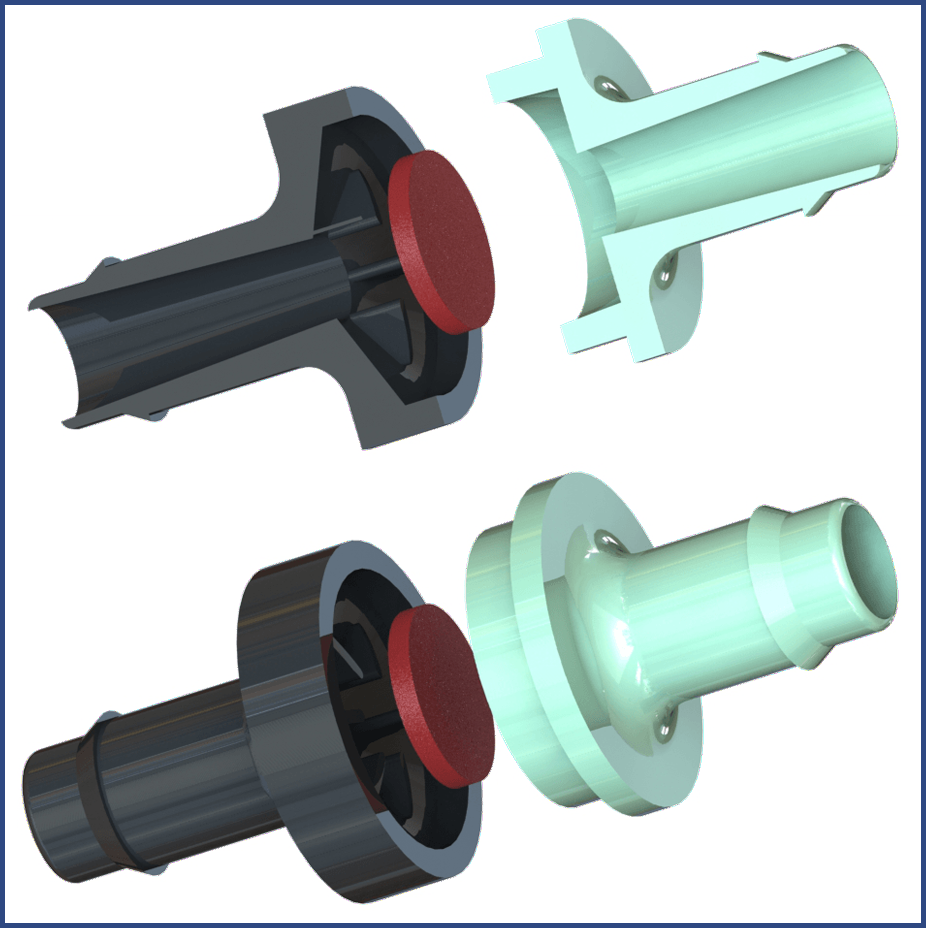

Ball Check Valves : Quick to respond, ball check valves use a spherical disc to control flow. They are versatile for both horizontal and vertical installations but may be limited in high-pressure applications and susceptible to wear.

A ball check valve is a type of check valve where the closing

member, the movable part that blocks the flow, is a spherical ball.

The ball moves up and down inside the valve depending on the flow

and seals against the machined seat when no flow or reverse flow

occurs.

Here's how it works:

- When the pressure behind the seat exceeds that above the ball, liquid is allowed to flow through the valve.

- Once the pressure above the ball exceeds the pressure below the seat, the ball returns to rest in the seat, forming a seal that prevents backflow.

- The ball rotates during operation, which helps to keep the valve clean.

Ball check valves are commonly used in wastewater applications,

fire protection systems, irrigation systems, and on the outlet side

of pumps to protect the pump. They are often preferred for use in

pumping stations as they are self-cleaning and require minimal

maintenance. If a ball check valve makes noise, it is typically due

to insufficient pump capacity or water hammer issues. Different ball

weights can be used to prevent these issues².

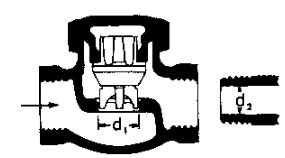

Diaphragm Check Valves : Diaphragm check valves utilize a flexible diaphragm to control flow. Virtually free from water hammer, they are suitable for slurry applications but may have limitations in high-pressure and high-temperature environments.

A diaphragm check valve is a type of non-return valve that is

commonly used in fluid handling systems to prevent backflow. It is

designed with a flexible diaphragm that seals against the valve body

to provide a tight shutoff and prevent fluid leakage.

Here's how it works:

- A self-centering flexible elastomer disc is the working part of this type of diaphragm check valve.

- The valve body keeps the disc centered over the seating area or sealing surface of the valve.

- The sealing surface is on the inlet side of the check valve body.

- Backflow causes the flexible rubber disc to lie down across the curved sealing surface.

- This closes the opening to the inlet port.

- The closed check valve prevents upstream flow back through the inlet port.

- Positive flow towards the outlet or exit port causes the disc to lie against this seat.

- The media then flows around the disc, through the channels and

out through the exit port of the check valve.

2. Design Considerations of Check Valves

2.1 Installation Orientation

Consider the orientation of check valves, whether vertical, horizontal, or angled. The choice depends on the specific requirements of the system.

2.2 Material Selection

Choose materials compatible with the fluid to avoid corrosion and ensure a long service life. Consider factors such as chemical resistance and durability.

2.3 Sizing and Flow Characteristics

Properly size check valves to match the pipe diameter, avoiding flow restrictions. Understand the flow characteristics to optimize performance.

2.4 Cracking Pressure

Set the cracking pressure, the pressure at which the valve starts to open, to prevent backflow and maintain system integrity.

2.5 Maintenance and Accessibility

Top

5 Most Popular

1. Pressure drop

2. Reynolds Number

3.

Pressure drop K coefficients

4. Churchill equation

5. Moody diagram

Prioritize valves with easy maintenance procedures and accessible

components. This ensures swift and efficient repairs when needed.

3. Troubleshooting of Check Valves

Check valves, while essential components in piping systems, can experience several common issues. Understanding these issues is crucial for efficient troubleshooting and maintenance. Here are some common problems associated specifically with check valves :

3.1 Reverse Flow or Backflow

Issue : One of the primary purposes of a check valve is to prevent

reverse flow, but if the valve fails to close properly, backflow can

occur.

Causes : Damaged or worn-out sealing surfaces, foreign objects

preventing proper closure, or incorrect installation.

3.2 Water Hammer

Issue : Rapidly closing check valves can generate a pressure wave

known as water hammer, causing stress on the valve and the piping

system.

Causes : Sudden valve closure due to high flow rates, incorrect

sizing of the valve, or lack of water hammer prevention devices.

3.3 Noise and Vibrations

Issue : Check valves, especially swing and lift types, can produce

noise and vibrations during operation.

Causes : Rapid closure, water hammer, or inadequate support for the

valve leading to vibrations.

3.4 Leakage

Issue : Check valves may experience leakage, allowing fluid to

pass through even when the valve is supposed to be closed.

Causes : Damaged seals, worn-out components, foreign material

preventing proper sealing, or incorrect installation.

3.5 Chattering

Issue : Chattering refers to the rapid opening and closing of the

check valve, causing wear and reducing its operational life.

Causes : water hammer, or inadequate sizing of the valve for the

specific application.

3.6 Cavitation

Issue : Cavitation occurs when vapor bubbles form and collapse

within the valve, leading to erosion and damage.

Causes : High-velocity flows, abrupt changes in pressure, or

improper valve sizing.

3.7 Failure to Open

Issue : In some cases, check valves may fail to open, hindering

the normal flow of fluid.

Causes : Sticking of the valve due to debris, inadequate spring

tension (in spring-loaded check valves), or issues with the hinge

mechanism.

3.8 Excessive Wear

Issue : Wear and tear on the moving parts of the check valve can

lead to reduced efficiency and eventual failure.

Causes : Continuous operation in abrasive conditions, lack of proper

lubrication, or using the valve beyond its specified service life.

3.9 Improper Installation

Issue : Incorrect installation can lead to various problems,

including inadequate sealing, increased wear, and reduced

performance.

Causes : Incorrect orientation, improper alignment, or not following

the manufacturer's installation guidelines.

3.10 Corrosion

Issue : Corrosion can deteriorate the material of the check valve,

affecting its structural integrity and performance.

Causes : Exposure to corrosive fluids, inadequate material

selection, or lack of protective coatings.

4. Minimum velocity for opening check valve : Calculation

Sources :

- Crane Co. Technical Paper No. 410 (Flow of Fluids Through Valves, Fittings, and Pipe)

- Valve Manufacturers Association of America (VMA) - Valve Basics

- Smith, L. (2018). "Fluid Mechanics of Valve Selection for Piping Systems." Journal of Fluid Dynamics in Piping Systems, 42(3), 215-230.