Vacuum systems : air leakage calculation, vacuum test, air

leakage test

Question or remark ? Please contact us at powder.process@protonmail.com

| Section summary |

|---|

| 1. Introduction |

| 2. Air leakage

calculation |

| 3. Air leakage Excel calculator |

1. Introduction

Air leakage tests for process vessels operating under vacuum are typically conducted to ensure the integrity and safety of the equipment. These tests are performed before the vessel is put into operation or whenever maintenance activities are carried out. When a vessel operates under vacuum, any leakage can lead to the ingress of atmospheric air, potentially compromising the vacuum conditions required for efficient and safe process operations.

Conducting air leakage tests involves having the vessel, or the system (if not only the vessel must be checked but for instance a piping) under vacuum, and then measuring the rate at which the vessel is picking up pressure. If there is a quick rise in pressure, it indicates that air is entering the vessel, suggesting a potential leakage point. Identifying and addressing leaks before the vessel is operational is crucial, as it minimizes production disruptions and prevents hazards associated with air and process material interactions. It should be noted that a vacuum test must be run in vacuum, some people or Artificial Intelligence may suggest to put the vessel under pressure and verify the rate of deflation but it is by no way equivalent to the vacuum test.

Furthermore, regular air leakage tests help maintain process efficiency, product quality, and operator safety. They are essential in industries such as pharmaceuticals, semiconductor manufacturing, and chemical processing, where even a small leak can have significant consequences. By ensuring the vessel's integrity, air leakage tests contribute to the overall reliability and performance of vacuum-operated process equipment.

2. Air leakage calculation

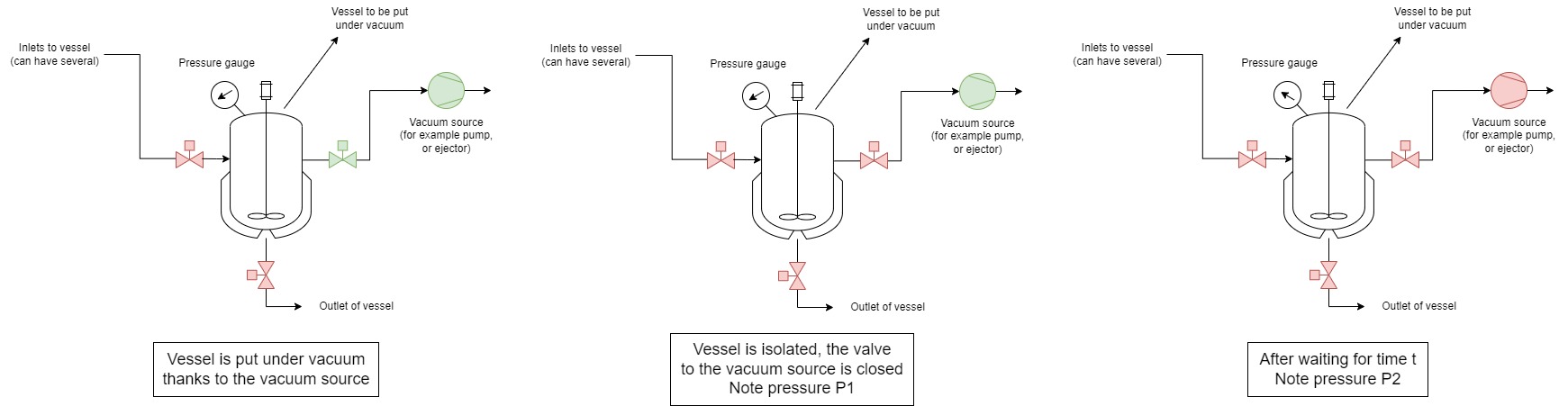

In order to carry out a vacuum test in order to estimate the air leakages to a vessel (or to another kind of system), the following must be done :

- Define the volume that will be put under vacuum

- Apply the vacuum with the regular pump or ejector used to create the vacuum

- Isolate the system from the vacuum source, make sure the system is closed

- Take reference of the pressure after isolating the system

- After a certain time, take a new reference of the pressure

- Make sure the pressure is always < 0.5 bar g (this is to make sure the air flow is sonic all along the test)

The air leakage can then be calculated with the following formula (SI) :

mair = 0.71*V*(DP) / t

With :

mair = Air leakage (kg/h)

V = System volume, vapor space, (m3)

DP = Pressure rise, difference in between both pressure measured (kPa)

t = time in between taking the 2 reference pressures (min)

In US units, the formula is :

mair = 0.006*V*(DP) / t

With :

mair = Air leakage (lb/h)

V = System volume, vapor space, (ft3)

DP = Pressure rise, difference in between both pressure measured (mmHg)

t = time in between taking the 2 reference pressures (min)

To detect if the isolation valve in between the system to put under vacuum and the vacuum source is leaking, you can conduct 2 tests, one with the vacuum source ON, one with the vacuum source OFF, if the result is the same, the valve is tight.

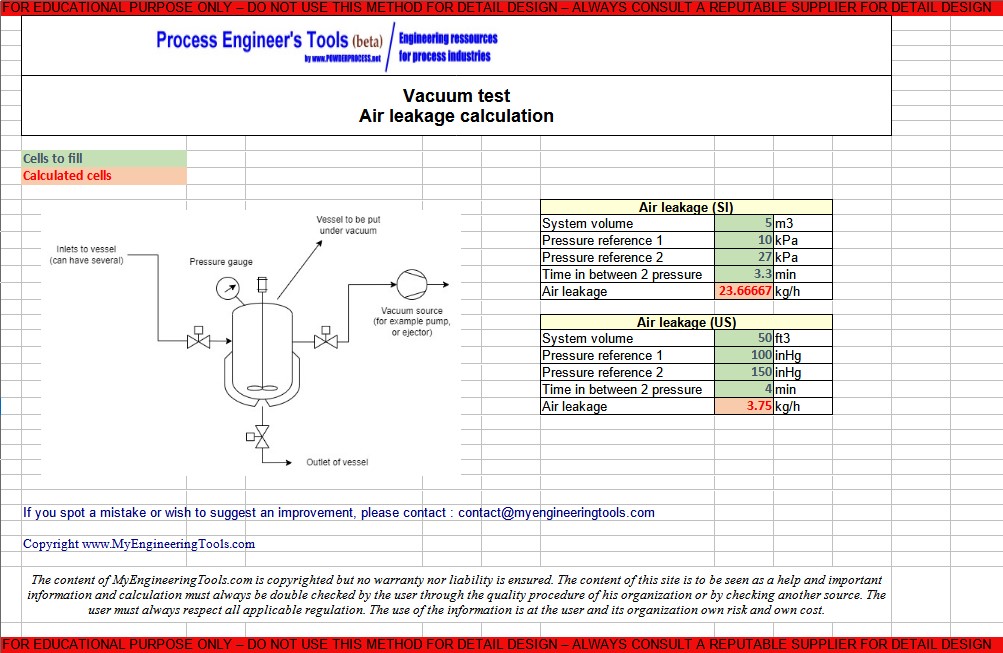

3. Air leakage Excel calculator

You can access a free Excel calculation tool to air leakage calculation explained above : Vacuum Test - Air Leakage calculator (click here)

Warning : this calculator is provided to illustrate the concepts mentioned in this webpage, it is not intended for detail design. It is not a commercial product, no guarantee is given on the results. Please consult a reputable designer for all detail design you may need.

Source

Rules of Thumbs for Chemical Engineers, Stephen Hall, IChemE, 2018