Demineralization of water : membrane area calculation step by

step

Follow us on Twitter ![]()

Question, remark ? Contact us at contact@myengineeringtools.com

1. STEP 1 : Gather data and requirements

2. STEP 2 : Calculate the flux of water through the membrane

3. STEP 3 : Calculate the membrane area required

4. STEP 4 : Calculate permeate and concentrate TDS

Deminarelization of water is an essential process step for the production of process or drinkable water. The demineralization can be performed thanks to membranes. The methodology below allows to estimate the membrane area required to demineralize a water stream at a given flowrate.

1. STEP 1 : Gather data and requirements

In order to size the membrane required for a demineralization operation, it is necessary to know the characteristics of the infeed water, the characteristics of the membrane to use, and to set some requirements in terms of nominal flowrate and characteristics of the permeate.

Input data :

TDS = Cf = feed water total dissolved solid

concentration (kg/m3)

kw = membrane flux rate coefficient (s/m)

ki = membrane mass transfer coefficient (m/s)

Process requirement :

Qp = permeate water flowrate (m3/s)

Cpmax = permeate maximum total dissolved solid

concentration (kg/m3)

ΔPa - ΔΠ = net operating pressure across the membrane

(kPa)

r = recovery rate (%)

Cc = concentrate total

dissolved solid concentration (kg/m3)

2. STEP 2 : Calculate the flux of water through the membrane

The flux of water by area of membrane can be calculated thanks to the flux rate coefficient of the membrane as well as the operating pressure to which the membrane is submitted. The flux of water can be calculated thanks to the following equation :

Fw = kw.(ΔPa

- ΔΠ)

With :

Fw = specific flow of water through the membrane (kg/m2.s)

ΔPa - ΔΠ = net operating pressure across the membrane

(kPa)

3. STEP 3 : Calculate the membrane area required

Knowing the specific flow through the membrane material considered, as well as the required flow of permeate to handle by the installation, the membrane area can be calculated (it is actually an estimation).

Membrane surface area calculation :

Qp = Fw ∗ A

A = Qp / Fw

With :

Qp = permeate water flowrate (m3/s)

Fw = specific flow of water through the membrane (kg/m2.s)

A = membrane required filtration area (m2)

Top 5 Most

Popular

1. Compressor

Power Calculation

2. Pump Power Calculation

3. Pipe Pressure

Drop Calculation

4. Fluid Velocity in pipes

5. Churchill Correlation

(friction factor)

4. STEP 4 : Calculate permeate and concentrate TDS

The concentration of the permeate can be calculated thanks to the following equation :

Cp = ki.A.Cf/(Qp+ki.A)

With :

Cp = permeate total dissolved solids concentration (kg/m3)

ki = membrane mass transfer coefficient (m/s)

A = membrane required filtration area (m2)

TDS = Cf = feed water total dissolved solid concentration

(kg/m3)

Qp = permeate water flowrate (m3/s), assumed

that Qp = r.Qf

r = recovery rate (%)

The concentrate concentration in total dissolved solid can be calculated thanks to the following equation :

Cc = (Qf.Cf - Qp.Cp) / Qc

With Qp = r.Qf and Qc = (1-r).Qf

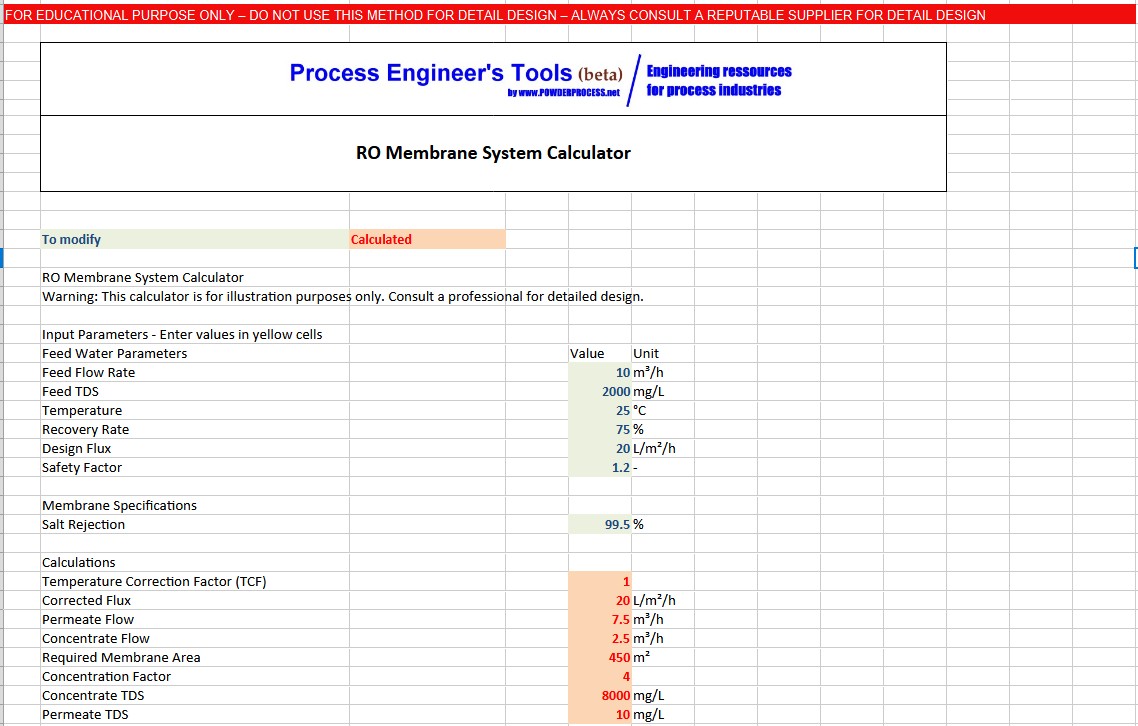

5. Membrane area estimation - Calculators

Warning : this calculator is provided to illustrate the concepts mentioned in this webpage, it is not intended for detail design. It is not a commercial product, no guarantee is given on the results. Please consult a reputable designer for all detail design you may need.

5.1 Excel calculator

You can download the Excel file here : download

5.2 Online calculator

RO Membrane surface estimation Calculator

Water Demineralization Systems

🔢 Calculation Steps

💡 Design Recommendations

Design Guidelines & Typical Parameters

Flux Rates (L/m²/h)

- Brackish Water: 15-25

- Seawater: 8-12

- Low Pressure: 20-35

- Nanofiltration: 20-40

Recovery Rates (%)

- Brackish Water: 70-85

- Seawater: 35-45

- Industrial: 60-80

- Per Element: <18

Salt Rejection (%)

- BW30: 99.5

- SW30: 99.8

- LPRO: 98.5-99.2

- Nanofiltration: 95-98

Operating Conditions

- Temperature: 15-35°C

- pH Range: 4-11

- Max Pressure: 600 psi

- SDI < 5

6. Types of Membranes

Different types of membranes are used in water demineralization:

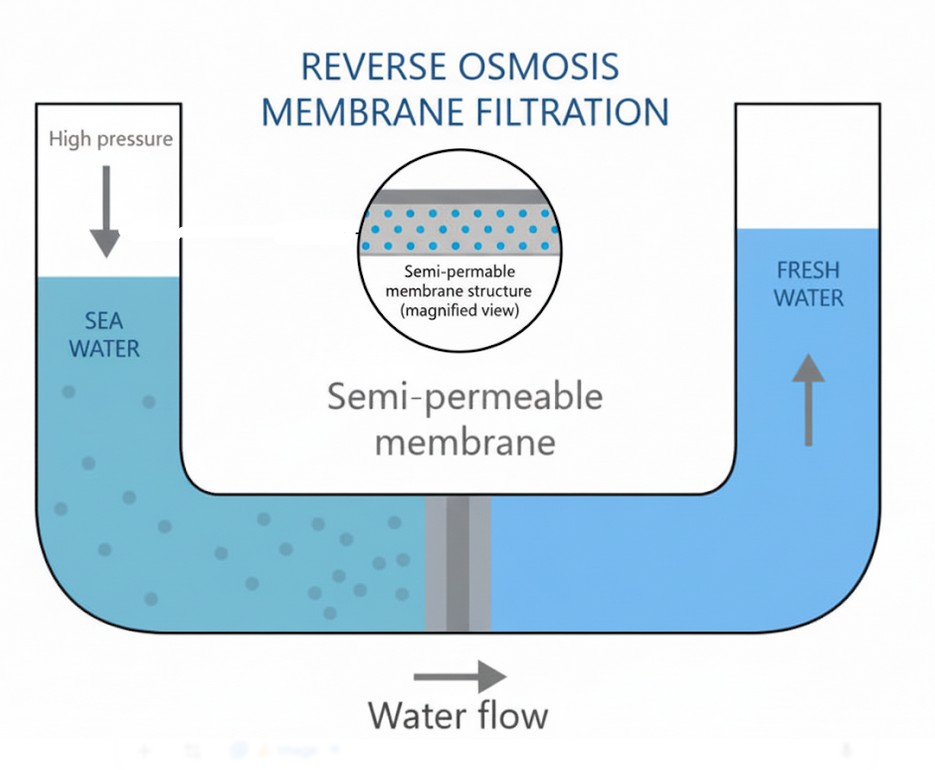

Reverse Osmosis (RO): A leading method for water demineralization that uses a semi-permeable membrane to remove minerals and dissolved solids.

Nanofiltration (NF): Used for removing divalent ions and larger molecules, suitable for applications needing partial demineralization.

Ultrafiltration (UF): Primarily used to remove macromolecules, suspended solids, and pathogens.

Electrodialysis (ED): Uses electrical currents to transport ions through selective membranes, reducing chemical usage.

7. Factors Affecting Membrane Performance

Several factors influence the efficiency and longevity of membranes in water demineralization:

Temperature: Higher temperatures generally increase flux but may also accelerate membrane degradation.

Pressure: Appropriate pressure levels must be maintained to ensure optimal flux without damaging the membrane.

pH Levels: Extreme pH levels can cause membrane degradation or fouling.

Fouling and Scaling: Accumulation of particles, biological matter, or scaling on the membrane surface can reduce efficiency and lifespan.

8. Pre-treatment Requirements

Pre-treatment processes are vital to protect the membrane and enhance its efficiency:

Filtration: Removes suspended solids and large particles that could foul the membrane.

Chemical Treatment: Adjusts pH levels and adds anti-scalants to prevent scaling.

Softening: Removes hardness-causing ions like calcium and magnesium.

Chlorination/De-chlorination: Controls microbial growth but must be managed to avoid membrane damage.

9. Energy Consumption

Energy usage is a significant consideration in membrane processes. Effective strategies to optimize energy consumption include:

Energy Recovery Devices: Utilize the pressure of the concentrate stream to reduce energy consumption.

Efficient Pump Systems: Use high-efficiency pumps to minimize energy usage.

Optimized System Design: Properly sized membranes and optimized operational parameters can lower energy requirements.

10. Maintenance and Cleaning

Regular maintenance and cleaning are essential for maintaining membrane performance:

Chemical Cleaning: Regular cleaning with appropriate chemicals to remove fouling and scaling.

Mechanical Cleaning: Physical cleaning methods to remove deposits from the membrane surface.

Monitoring and Inspection: Regularly check membrane performance metrics and inspect for signs of wear or damage.

11. Applications of Demineralized Water

Demineralized water finds applications in various industries:

Pharmaceutical Industry: High purity water is essential for drug formulation and manufacturing.

Electronics Industry: Used in the manufacturing processes to avoid contamination and ensure product quality.

Boiler Feedwater: Prevents scaling and corrosion in boilers.

Laboratory Use: Ensures accurate and uncontaminated test results.

FAQ: Demineralization of Water - Membrane Area Calculation

1. What is demineralization of water, and why is it important?

Demineralization is the process of removing dissolved solids (TDS) from water to produce process or potable water. It is essential for ensuring water quality in industrial and drinking water applications.

2. What data is required to calculate the membrane area for demineralization?

Required data includes feed water TDS concentration, membrane flux rate coefficient (\( k_w \)), membrane mass transfer coefficient (\( k_i \)), permeate flow rate (\( Q_p \)), and operating pressure (\( \Delta P_a - \Delta \Pi \)).

3. How is the flux of water through the membrane calculated?

The flux (\( F_w \)) is calculated using the formula: \[ F_w = k_w \times (\Delta P_a - \Delta \Pi) \] Where \( \Delta P_a - \Delta \Pi \) is the net operating pressure across the membrane.

4. How is the required membrane area determined?

The membrane area (\( A \)) is calculated using: \[ A = \frac{Q_p}{F_w} \] Where \( Q_p \) is the permeate flow rate and \( F_w \) is the water flux through the membrane.

5. What is the recovery rate, and how does it affect the process?

The recovery rate (\( r \)) is the percentage of feed water that becomes permeate. Higher recovery rates increase concentrate TDS and may require larger membrane areas.

6. How is permeate TDS concentration calculated?

Permeate TDS (\( C_p \)) is calculated using: \[ C_p = \frac{k_i \times A \times C_f}{Q_p + k_i \times A} \] Where \( C_f \) is feed water TDS and \( k_i \) is the mass transfer coefficient.

7. How is concentrate TDS concentration calculated?

Concentrate TDS (\( C_c \)) is calculated using: \[ C_c = \frac{Q_f \times C_f - Q_p \times C_p}{Q_c} \] Where \( Q_f \) is feed flow rate and \( Q_c \) is concentrate flow rate.

8. What are typical flux rates for different water types?

Typical flux rates (L/m²/h) are: - Brackish water: 15-25 - Seawater: 8-12 - Low pressure: 20-35 - Nanofiltration: 20-40.

9. What are typical recovery rates for different applications?

Typical recovery rates (%) are: - Brackish water: 70-85 - Seawater: 35-45 - Industrial: 60-80.

10. Are there tools available to estimate membrane area?

Yes, our website offers a free Excel calculator and an Excel tool to estimate the required membrane area for demineralization.

Sources

[Chopey] Handbook of Chemical Engineering calculations, Chopey et al, McGraw Hill, 2004