Pumps : free online Process Engineering Handbook

Process Engineer's Tools has selected here all the key knowledge Engineers working with fluid flow / fluid dynamics need to solve industrial problems or simply get a handy reminder when required. Bookmark the page for future reference !

PUMPS

Pump Performance characteristics

Explore the significance of pump characteristic curves, a crucial tool for pump selection and system design. Gain insights into how these curves change with varying pump speeds and fluid viscosities. Understanding these curves helps you make informed decisions about pump performance and system efficiency.

Pump Performance characteristics changes

Discover the importance of pump characteristic curves in selecting and troubleshooting pumps. Learn to approximate performance changes when altering pump speed or impeller diameter. Additionally, understand how viscosity impacts pump performance and use a viscosity correction chart for calculations.

Pump

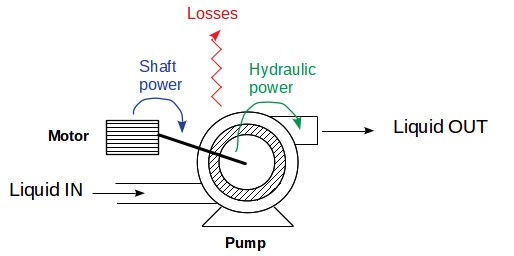

Power Requirements calculations

Learn about pump hydraulic and shaft power, essential for motor sizing. Calculate the hydraulic and shaft power using flow rate, head, and fluid density. Discover how to estimate installed power and access a free Excel calculator for quick and accurate power calculations.

Pump Head

Learn what pump head is, how to

calculate it, and its importance in pump characteristics.

Understanding pump head helps you make informed choices when

working with pumps.

Pump

Specific Work

Learn how to calculate the specific

work of a pump and the power gained by the fluid as it passes

through the pump. This practical guide provides step-by-step

instructions for performing these calculations and offers valuable

insights for real-world applications. Whether you're a student or

a professional in the field, understanding these concepts is

crucial for pump system design and analysis.

Pump Efficiency

Discover what pump efficiency is and

how to calculate it. Learn about the three key efficiencies -

hydraulic, mechanical, and volumetric - and how they contribute to

a pump's overall efficiency. This knowledge is essential for

selecting the right pump for your needs.

Pump NPSH

Understand pump NPSH (Net Positive Suction Head) and why it's crucial for proper pump operation. Learn how to calculate NPSH required and available, and discover the impact of insufficient NPSH on your pump's performance. This knowledge is essential for ensuring your pump works efficiently.

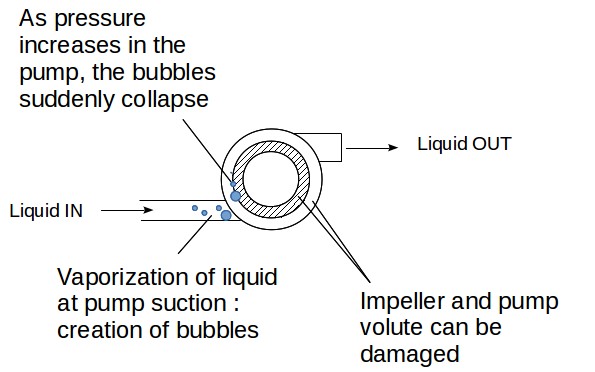

Pump

Cavitation

Learn about pump cavitation, a harmful

phenomenon caused by vaporization at the pump impeller's entrance.

Discover the risks and consequences of cavitation and how to

prevent it through proper design and understanding of Net Positive

Suction Head (NPSH) requirements.

Minimum flow required for centrifugal pumps

Discover why maintaining a minimum flow

rate through a centrifugal pump is essential. Learn how to

calculate this flow to prevent issues like cavitation and protect

your pump from damage.

Pumps full torque

load

Learn about full load torque and how to

calculate it for a centrifugal pump. Understand the relationship

between pump power, speed, and torque to ensure efficient pump

operation.

Top 5 Most

Popular

1. Compressor

Power Calculation

2. Pump Power Calculation

3. Pipe Pressure

Drop Calculation

4. Fluid Velocity in pipes

5. Churchill Correlation (friction

factor)

Parallel or Series operation

Learn about parallel and series pumping

for pumps. Understand how to operate pumps in parallel or series

and the associated advantages and disadvantages. Discover the

potential problems and precautions for reliable and efficient

operation.

Optimizing Industrial Operations: Mastering Pump System Efficiency for Energy Savings

Enhance your pump systems' efficiency

with practical insights. From mastering fundamental parameters to

leveraging cutting-edge technology, this page guides you through

optimizing pump performance. Explore pump curves, efficiency

mapping, and strategies like variable speed drives, right sizing,

and regular maintenance. Delve into parallel pump operation and

optimal pipe sizing. Embrace Industry 4.0 with smart monitoring

systems and choose energy-efficient pump designs for a sustainable

and cost-effective solution. Upgrade your pump systems knowledge

for improved industrial processes.

Temperature rise in centrifugal pumps

Understand temperature rise in centrifugal pumps and its impact. Learn how to calculate temperature increase at no flow, low flow, and normal operation. Avoid pump damage with our calculation tools in both US and SI units. Ensure optimal pump performance and prevent thermal issues.

Twin

screw pump guide : Design, Applications, and Maintenance

This guide covers the essential aspects of twin screw pumps, including their design features, operational advantages, and versatility across industries like oil and gas, food and beverage, and chemical processing. It explains the key factors in sizing, the ability to handle fluids with varying viscosities, and maintenance tips to ensure long-term reliability. The document also provides solutions for common issues, emphasizing the pump’s unique capabilities like self-priming, reverse operation, and dry running tolerance.

Centrifugal

Pumps Shut Off Head calculation

Insightful analysis of centrifugal pump shut-off head, detailing its definition, determination methods, and associated risks. It highlights the importance of manufacturer-certified pump curves over empirical estimations and discusses thermal, mechanical, and hydraulic risks of near shut-off operation. Practical examples illustrate shut-off head calculations and safe operating times, emphasizing the need for accurate data and testing to ensure pump reliability and efficiency. Key takeaways include prioritizing certified data, quantifying thermal risks, and identifying stable operating envelopes through comprehensive testing.